Offseason '25 | Carbon Fibre Shafts

29 Dec 2025

In 2025 we utilised Carbon Fibre for the first time, both in static structure and as a replacement for hex shaft.

We found some great benefits of doing this, however being our first time we also ran into multiple issues. The purpose of this blog post is to detail our solution to the problem of robust bearing support.

This project was under taken by a collection of grade 9 students.

Reflection on 2025

On our 2025 robot, we secured our CF shafts to our structure using HDPE bushings with aluminium runners. This was step one in weight reduction, removing the mass of a large heavy bearing. One issue we found with this, was that the increased friction generated heat which in some locations made the bushing bind. Other than that the function met or exceeded our expectation.

Solution for 2026

Our solution was utilising the following as KPIs:

No wear on the carbon fibre shaft after 30 minutes of use at a 5-10 degree angle for a 1kg weight/load (fail state)

It should be less than 20 grams so it is less or equal to a normal hex bearing

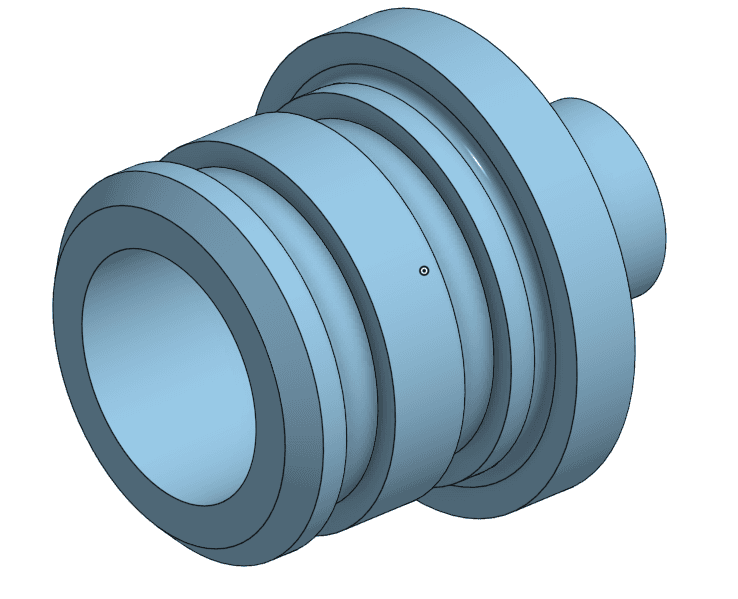

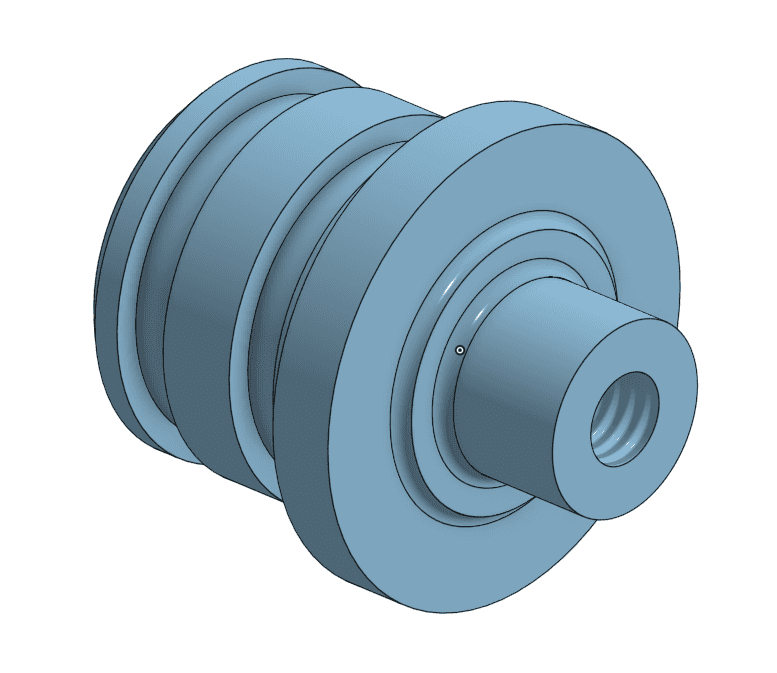

Our design had several undocumented iterations, but our final solution is a plug that is epoxied into a CF shaft, and a flanged bearing that is held in by a custom bearing hat.

Budget Proposal

Item | Link | Quantity | Price | Notes |

M4 Length 10mm Low Profile Bolt | 1 | $0.44 | Shipping not included, check link, need 1 but comes in 10 | |

Round aluminium | 1 | $0.20 | Will be made by techies (39.24 for 4m of round aluminium) | |

7X17X5 bearings | 1 | $1.14 | Get the F697ZZ 7X17X5 flange bearing, need 1 but comes in 10 | |

M3 Length 25mm Low Profile Bolt | 1 | $0.55 | Shipping not included, check link, need 1 but comes in 10 | |

Carbon Fibre (500mm) | 2 | $[27.34] | carbon fibre to test on | |

TOTAL | $2.33 | it costs this much to make 1 thing | ||

Onshape CAD